I have been loading on a Dillon 650 since the late 1990s. Great machine, but you need to make careful adjustments when you change cartridges. (I reload 29 different metallic cartridges counting wildcats… also have 3 MEC presses for the shotgun reloads).

I started reloading in 1962 and have gone through several different reloading benches.

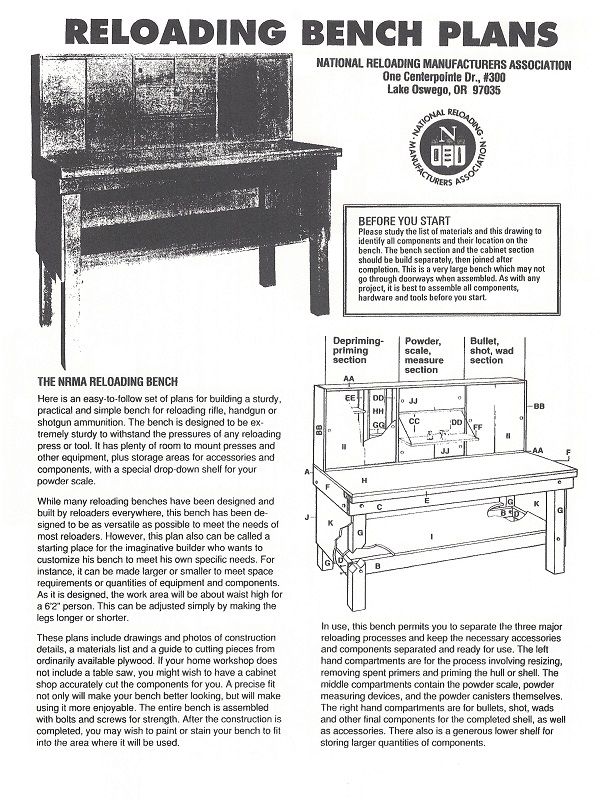

Absolutely the best one is the NRMA designed bench.

I believe that plans are still available. Mine is over 30 years old.

It is super strong, but what I like most about it is that it is a simple takedown into several components by removing the 3/8 inch carriage bolts that hold it together. This makes transport a lot simpler and getting through doors a breeze. I flew helicopters for 26 years, and moved quite often. Having this bench really was a boon to my reloading.

Besides my two Dillon presses I have three MEC presses and several other bench mounted tools.

Only using one tool at a time was a problem until I modified the bench with a key system for mounting the tools when I rebuilt the bench about 20 years ago. (I had originally dyed the bench a dark walnut stain. This turned out to be a poor choice because it hid dropped powder and other small dropped objects.) I simply added a ¾ inch maple plywood sheet on top. Before I installed the new bench top I cut out the key hole.

The largest tool footprint was my MEC Grabber, so I designed the key to accommodate it, and thus all others.

I ended up with an 11 x 11 inch ¾ inch thick key block with ¼ inch holes set 1 inch from the edges in each corner. I glued an 11x11 inch piece of 1x12 on top of the plywood key to give the mounting bolts a little more material to work with.

¼ inch holes were drilled through the bench and the underside was relieved using my Mototool to accommodate ¼ wing nuts. These were secured using fiberglass rifle bedding compound and are totally solid.

This is a picture of my bench with a key installed that allows the full use of the bench without having to work around any mounted tools.

This is a picture of my bench with a key installed that allows the full use of the bench without having to work around any mounted tools.

Here is a good look at the key slot showing the modifications I made to allow shotgun primers to drop into a catch jar mounted under the bench top.

Here is a good look at the key slot showing the modifications I made to allow shotgun primers to drop into a catch jar mounted under the bench top. One of my MEC 600 Jrs. set up for 20 GA. Showing the modification for the primer drop.

One of my MEC 600 Jrs. set up for 20 GA. Showing the modification for the primer drop. Here is how the MEC Grabber fits the key.

Here is how the MEC Grabber fits the key.

All of the presses are mounted using the appropriate size countersunk screw from below and lock nuts on top. This makes for a very solid mount. I have no trouble swaging bullets.

Here is the bottom of my Pacific “O” press showing the countersunk screws.

Here is the bottom of my Pacific “O” press showing the countersunk screws.

This is the Pacific press mounted and ready to use.

This is the Pacific press mounted and ready to use.

Pacific was bought out by Hornady in the late 1980s.

(All the 22 rimfire ammunition was for a test of modifying the bullets.

Several machinist/gunsmiths offer tools and or dies to form several different configurations…

Due to the 22 rimfire drought, this test was put on hold.)

Here is my 650 mounted and ready to go through another batch of 500 brass in an afternoon.

Here is my 650 mounted and ready to go through another batch of 500 brass in an afternoon.

Tool change out is simply pulling the four ¼ in lug bolts, lifting off one press and setting on the other. Tighten down the very same lug bolts and I am ready for the next job.

As to bench height, I chose to make it comfortable to stand while reloading.

The addition of a bar stool, allows me to sit if I wnat to.

It is not necessary to build as heavily as I did.

But the key system works very well for me and could be adapted to a smaller bench.

I hope this gives you some ideas.

Good luck with the 650, you are going to love it.

Steve